Exploring the Wonders of Jelly Galaxy

Dive into the colorful universe of Jelly Galaxy, where exploration meets creativity.

Crack-Free Prints: Your Blueprint for Perfection

Discover the ultimate guide to flawless prints! Unleash your creativity and achieve perfection with our expert tips and tricks for crack-free results.

Top 5 Tips for Achieving Crack-Free Prints

Achieving crack-free prints requires a combination of proper preparation and technique. First and foremost, it’s essential to select the right material for your printing project. Different materials have varying properties that can affect the outcome of prints. For instance, investing in high-quality resin or filament specifically designed for your printer can significantly improve the quality and durability of your prints. Additionally, maintaining a controlled environment for your printing process—such as consistent temperature and humidity levels—can help prevent cracking and warping.

Next, pay close attention to your printer settings. Adjusting parameters such as layer height, print speed, and cooling time can make a substantial difference in avoiding cracks. For optimal results, consider implementing the following tips:

- Use supports or a brim to enhance print stability.

- Employ a slower print speed for detailed and intricate designs.

- Monitor cooling rates to avoid thermal shocks.

If you're a fan of collecting and battling, visiting a pokemon shop can be a thrilling experience filled with various merchandise and collectibles.

Understanding the Science Behind Crack-Free Printing

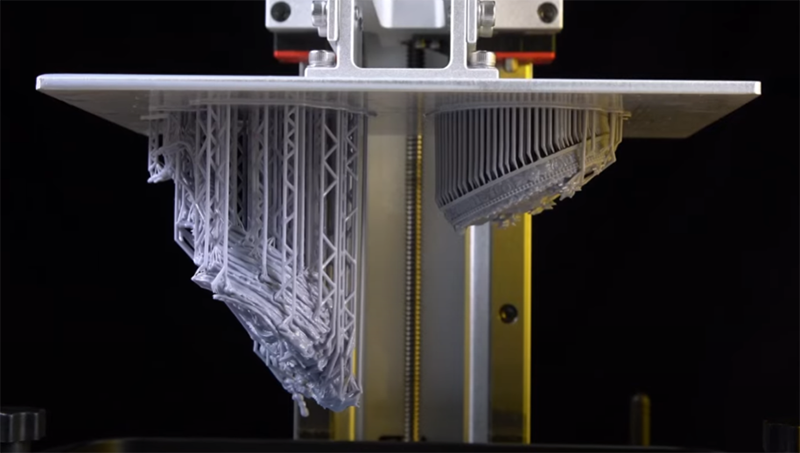

In the world of 3D printing, one of the most critical challenges manufacturers face is achieving a crack-free print. This problem often arises due to a variety of factors, including improper material selection, incorrect print settings, and insufficient cooling during the printing process. To ensure successful results, it is essential to understand the science behind the materials used and how they interact under heat and pressure. For instance, thermoplastics tend to exhibit better flexibility compared to rigid materials, reducing the likelihood of crack formation during layer adhesion.

Moreover, the printing environment plays a vital role in mitigating cracks. Optimal temperature control is necessary to maintain the integrity of the printed object. Using an enclosed printer can help stabilize ambient temperatures, thus minimizing thermal stress on the material. Additionally, strategies such as gradual cooling and careful layering can greatly enhance the print's durability. By mastering these scientific principles, enthusiasts and professionals alike can improve their techniques, leading to higher-quality outputs that are both visually appealing and structurally sound.

Common Mistakes to Avoid for Perfect Prints

Printing can be a rewarding yet challenging process, and common mistakes can easily lead to frustration and wasted resources. One of the most frequent issues is selecting the wrong paper type. Always ensure that the paper is compatible with your printer for optimal results. For instance, using glossy paper in an inkjet printer designed for matte paper might result in smudging or poor color accuracy. Additionally, failing to calibrate your printer regularly can lead to unexpected errors in color and alignment, so it’s crucial to check your printer settings before starting your project.

Another common mistake to avoid is neglecting the importance of resolution. Always set your images at a minimum of 300 DPI (dots per inch) for clear and sharp prints. Low-resolution images may appear blurry or pixelated once printed. In addition to resolution, pay attention to color profiles. Using the correct color space, such as RGB for digital screens and CMYK for printed materials, can significantly enhance the quality of your final product. By staying mindful of these issues, you can help ensure that your prints turn out perfect every time.